- Home

- About

- Industries

- Solutions

- Products

Air Purifiers

Equipment

Others [Technology & Accessories]

- Sensor 360®

- Media Pads & Rolls

- Frames & Latches

- Success Stories

- Digital Binders

Air Purifiers

Equipment

Others [Technology & Accessories]

Customer Profile

The imperial futuristic city project designed with opulent building area across the province planned to have multiple palaces. The palace area was designed with modern and traditional Moroccan-style architecture featuring Islamic designs and colourful ceramic tiles. The complex of planned palaces in this city include helipads, a marina and a golf course. 26,500 square km (10,230 square miles) zone dedicated to several industries, including biotechnology, water, food, energy, water and entertainment.

Filtration Situation

The service area of the high-profile end-user in the Middle East planned to have a data center, administrative block, kitchen, accommodation for service help, pantry area and a sewage treatment plant in its main complex.

The administration observed that the sewage treatment plant generates odour that can be strong, persistent and a nuisance to residents, employees, businesses and industries located near the treatment plant.

Nuisance odours often emerge from the combined sewer overflow (H2S, SOX, Ammonia, BTEX, TCE, and other VOCs), industrial sewage (benzene, industrial chemical effluents such as amines, and other VOCs) and residential sewage (ammonia, hydrogen sulphide and mercaptans). The gas contaminants can generate odour, which is health-irritant to humans and cause corrosion issues to mechanical and electronic equipment. The management decided to investigate the solution to protect the environment of the service area from the harmful odour and gas emissions of STP.

The AAF International Solution

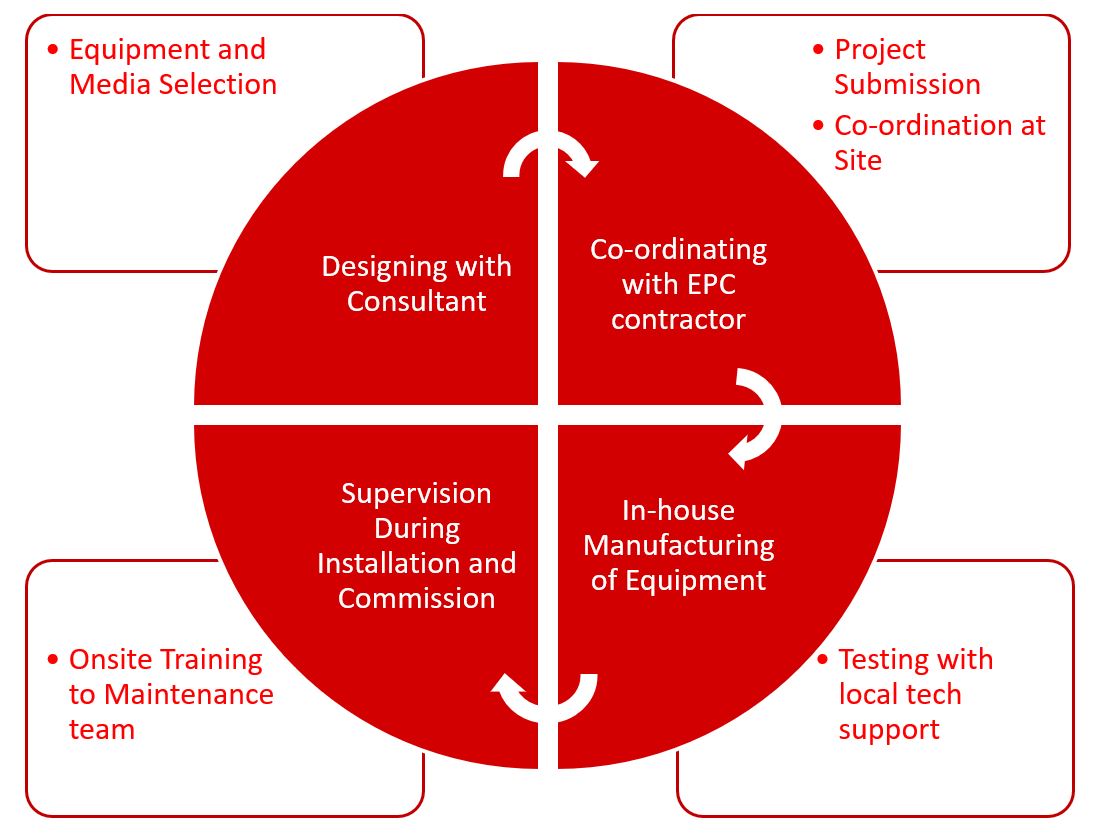

The consultant invited various air filtration companies to design and propose their exhaust ventilation filter solutions. Design engineers from AAF presented a study on expected gases from STPs and how gas-phase solutions would be the best solution to control the odour and also can prevent the corrosion which can occur at the nearby data centre and electronic equipment rooms. The design plan included other areas such as service areas for kitchen exhaust air filtration system and the appropriate filter for AHUs. The AAF filter solution was selected over the other global filter manufacturers.

Then, the nominated MEP contractor worked under AAF guidance to build the planned STP air filtration design – the heavy-duty gas-phase equipment at the exhaust of the STP and passive scrubber units at the lifting stations.The exhaust system included 3 stages of the media bed. The media was selected based on the application area and the gas concentration provided during the project design stage.

For the underground sewer vents reaching to the lifting areas which was passing through the recreational areas and golf course area, AAF recommended passive equipment that adsorbs the odour from the gases released.

Results

This project was awarded to AAF considering its technical expertise and capabilities in the filtration. AAF was actively involved in designing, manufacturing, testing and commissioning of gas-phase solutions throughout the project which took around one and a half years to complete.

After testing and commissioning of AAF gas phase products, the project owners were pleased with the solution provided and the continuous support they received and awarded a recommendation letter by project contractor for our services.

The success of this prestigious project proves that AAF is the world leader in providing effective air filtration solutions to meet all demanding conditions.