Protection of Invaluable Artifacts in One of the Iconic Museums

LOCATION: Middle East

SEGMENT

• Unique architectural design museum attracts 3,000 tourists(approx.) per day

• AAF partnered with one of the leading AHU manufacturers

Preserving historic objects and collectibles can generate many challenges to museums and historic storage facilities. The futuristic 52,000-square-metre museum was conscious of airborne pollutants and gaseous contaminants to protect their priceless collections of artifacts, historical assets, artwork, and literature. Additionally, providing good indoor air quality was equally important to them.

Typical gases found in museums and historic storage facilities include hydrogen sulfide, nitrogen dioxide, sulfur dioxide, formaldehyde, ozone, formic acid, acetic acid, carbonyl sulfide, halogens (chlorides, fluorides, iodides). Poor IAQ also can have adverse health effects on employees and visitors.

Filtration Situation

The new national museum was an important and dynamic arena for the general public to meet the visual arts and various national and international preservations. The museum gives voice to unique stories of the region and exhibits various international artifacts. Numerous, priceless historical objects and rare collectibles were planned to exhibit in this huge museum.

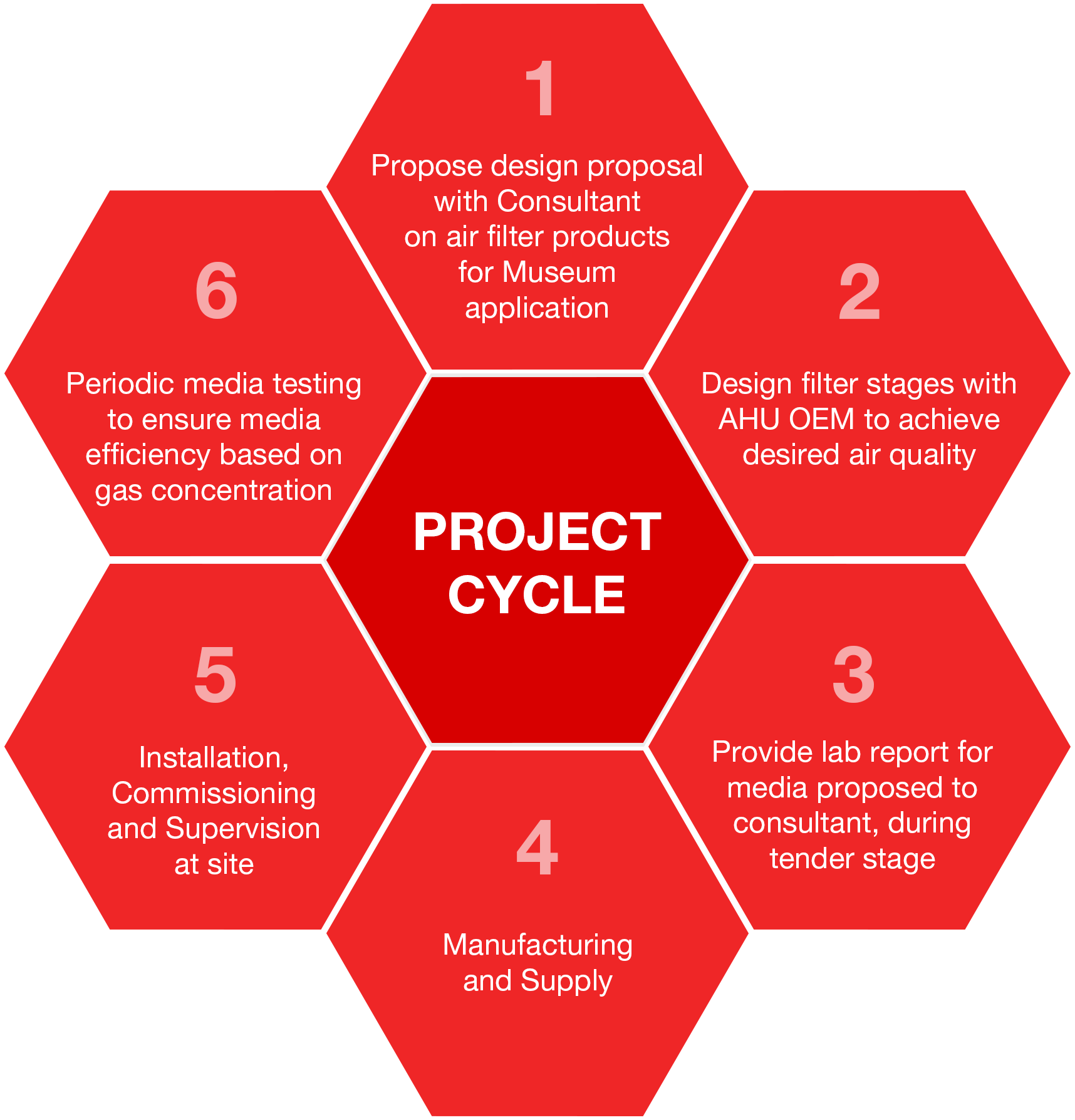

The project engineers were concerned about the damaging effects of air pollutants. Hence the project awarded to leading AHU manufacturer. They join hands with AAF to provide an optimized filter solution for this prestigious project.

Since AAF experts worked on the initial air quality test report provided to the consultant, they recommended the design based on similar applications focusing on energy saving, filter lifecycle and removal of gaseous contaminants. These specifications were provided to AHU manufacturing vendors along with the filtration stages.

During the design phase, AAF proposed the solution (media selection) based on air quality issues according to the surrounding environment, air exchange rate, temperature, humidity and surface adsorption and the artifacts planned to protect in the museum.

The AAF International Solution

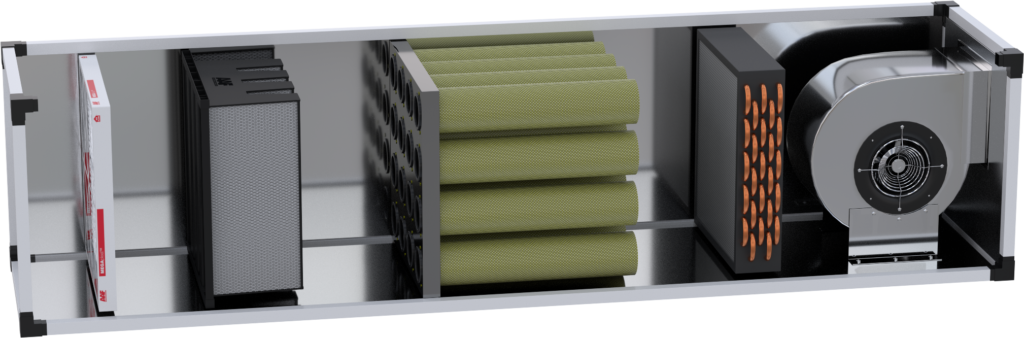

Since the museum had multiple AHUs and the area demonstrated is huge, the whole analysis took a few days. Once the analysis is done with the required tests, AAF suggested particulate filters based on energy-saving theory and gas-phase filters with activated impregnated carbon to tackle gaseous contaminants. While providing the solution, AAF submitted their media performance report for adsorption capacity and lifetime.

Pre-filters recommended by AAF were pleated panel filter. They are the strongest and most long-lasting MERV 8 filter in the market. When it comes to fine filters, box filters with greater airflow capacity, low resistance and maximum dust holding capacity were recommended. The box type filter design gives an advantage on the footprint AHU.

The suggested gas phase filter has a unique seal that holds in the frame and bayonet-style clamping mechanism. It can be assembled into a galvanized sheet metal holding frame to fit standard dimension filter sections in air handling units.

Results

AAF bagged the complete project to provide the entire filtration solution for AHU manufacturer. The customer gained confidence in the media selection by AAF by conducting a third-party media test on our media for various gas concentrations. The results convinced the customer on the right selection of the media, adsorption capacity and efficiency of the gas-phase media used.

As a part of the contract, AAF conducted media test on a periodic basis. This helps the customer to understand the replacement of the media in advance. This analysis helped the customer to save total maintenance and operational cost.

AAF’s local presence, technical assistance, after-sales service and global references helped the customer understand and appreciate AAF’s competence to provide the best filtration solution for this magnanimous project.